Safety Innovation! Efficient & Environmentally Friendly for Law Enforcement Agencies with reduced CO2 emissions

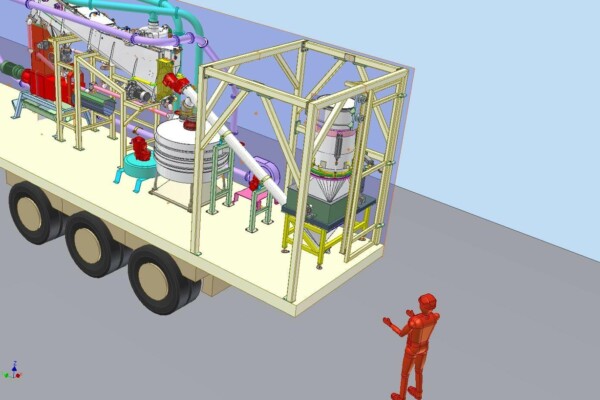

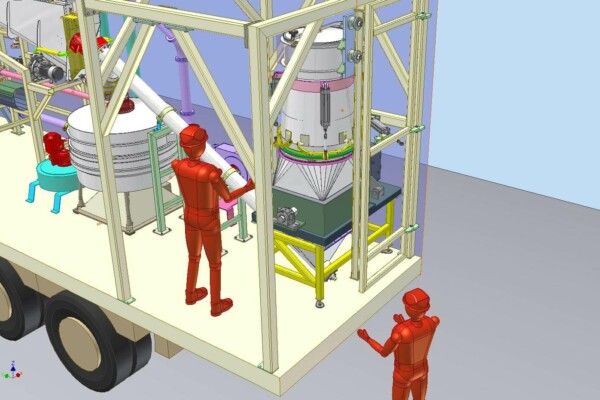

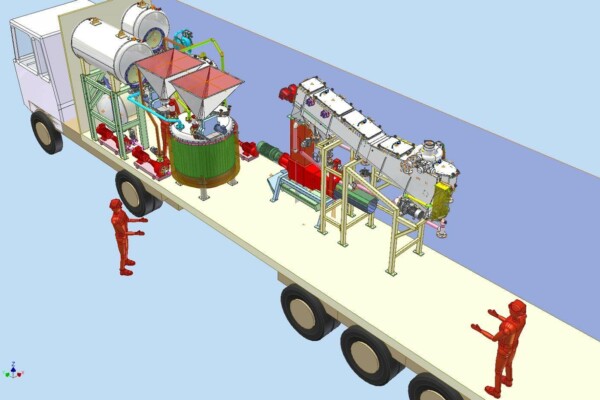

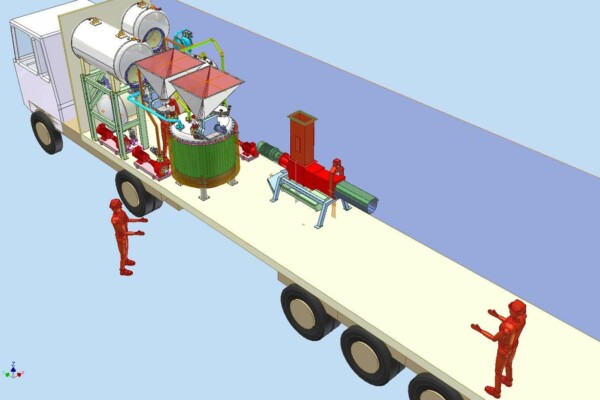

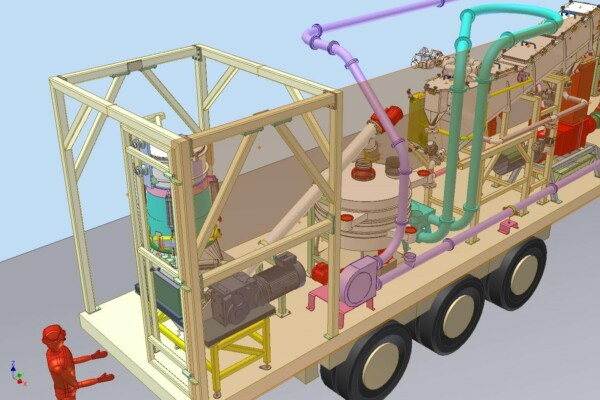

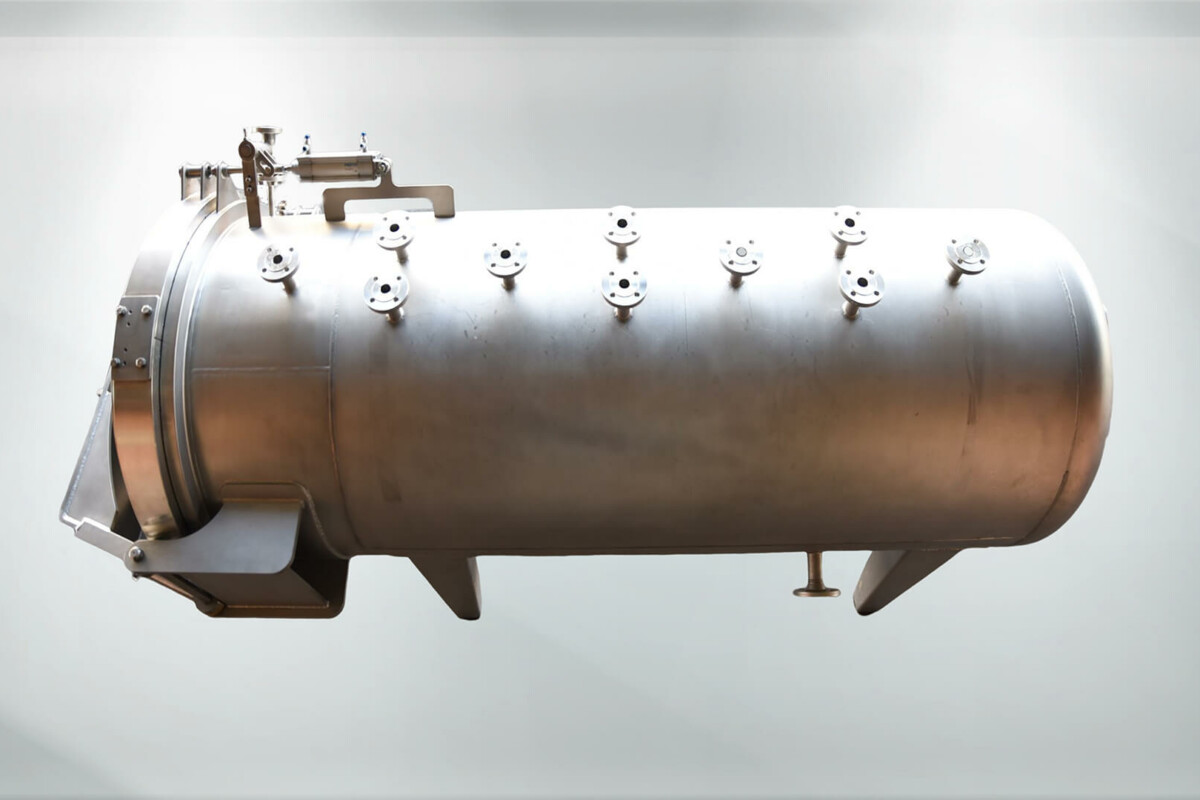

The Alka Eco Mobile DDU (Drug Destruction Unit) System by innovator Ludwig Marie Louis de Haan is an advanced solution for law enforcement agencies and drug disposal facilities, designed to efficiently and safely destroy a wide range of seized drugs on site! Available primarily as mobile versions (on a truck) and on request as a stationary version, it offers flexibility and effectiveness in drug disposal. Our innovation systems are designed to meet the highest standards, and we’re currently pursuing key certifications, including CE and ATEX (for the shredder, if you require a system that unpacks the drugs for you), to ensure compliance with industry regulations.

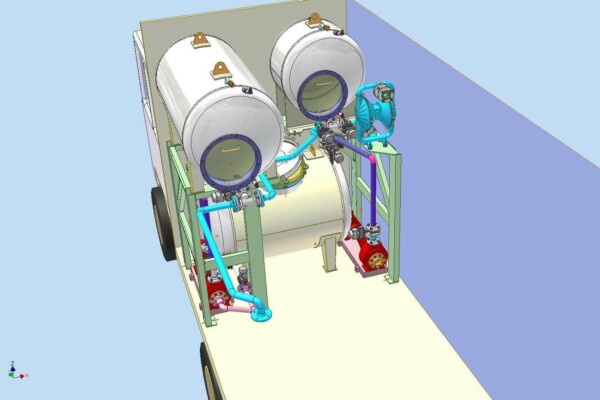

We offer drug destruction units in various capacities. The compact unit is capable of handling weights ranging from grams to several hundred grams. This design is ideal for police and depots. Once the analysis is complete, the police can quickly defuse the drugs themselves. No further transport is required.

The mobile unit offers the same capabilities and can weigh up to approximately 3000 kg. You can set up the industrial stationary unit as a permanent installation in the ports, serving as an alternative to the incinerators. Burning drugs is always harmful to the environment. In all cases, road transport is no longer necessary, and there is no risk of armed robberies, transports, and storage depots.

Emmo Meijer (see my website) told the Dutch police in September 2023 that incinerators will go to a very low level (in terms of numbers) soon. BURNING OF DRUGS IS VERY BAD FOR THE ENVIRONMENT.

Our innovations are the most environmentally friendly alternatives.

Ideal Use Cases: Law Enforcement Agencies for drug seizure operations, Customs and Border Protection for contraband disposal on-site, or directly in the harbours, immediately after analysis.

Safety innovation: No more risks for armed robbery at depots—where drugs need to be stored prior to fire destruction—and no more armed road transports are needed.

185 KW is the total gross KW. But, our energy recall system, enables savings from 50-80%. This is based on calculations, on March 12, 2021, by Ingenieur Jürgen Stichling Ing. Büro Stichling, Pfaffenhofener Str. 4, 86564 Niederarnbach, Germany.

In start mode, the total power consumption is theoretical 185KW, but that is gross. Since our energy recall system is generating savings of 50-80%, the gross KW is not applicable for a complete first cycle, and each new cycle, with re usage of the hot Effluent, your net energy, water, chemicals cost is even lower.