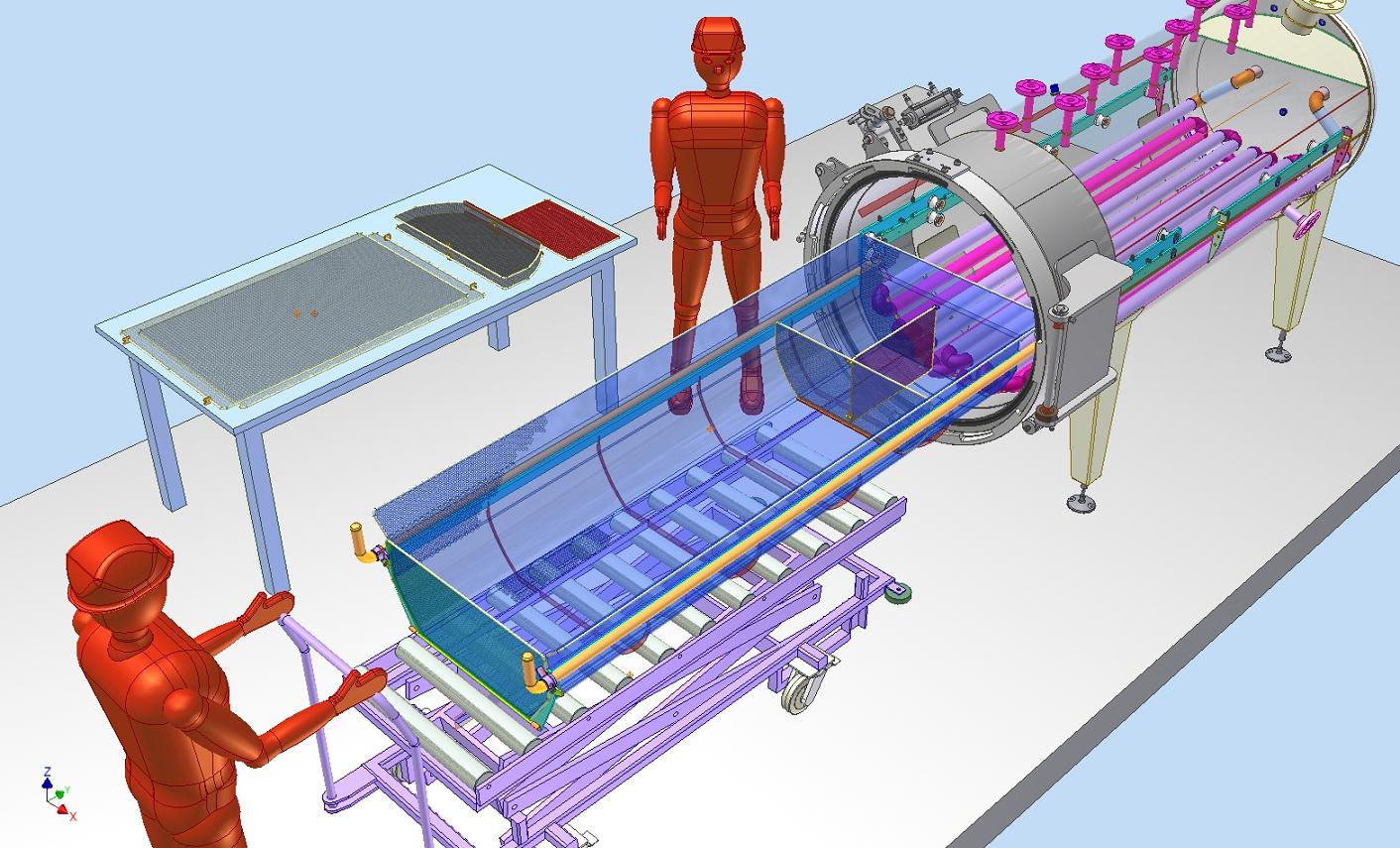

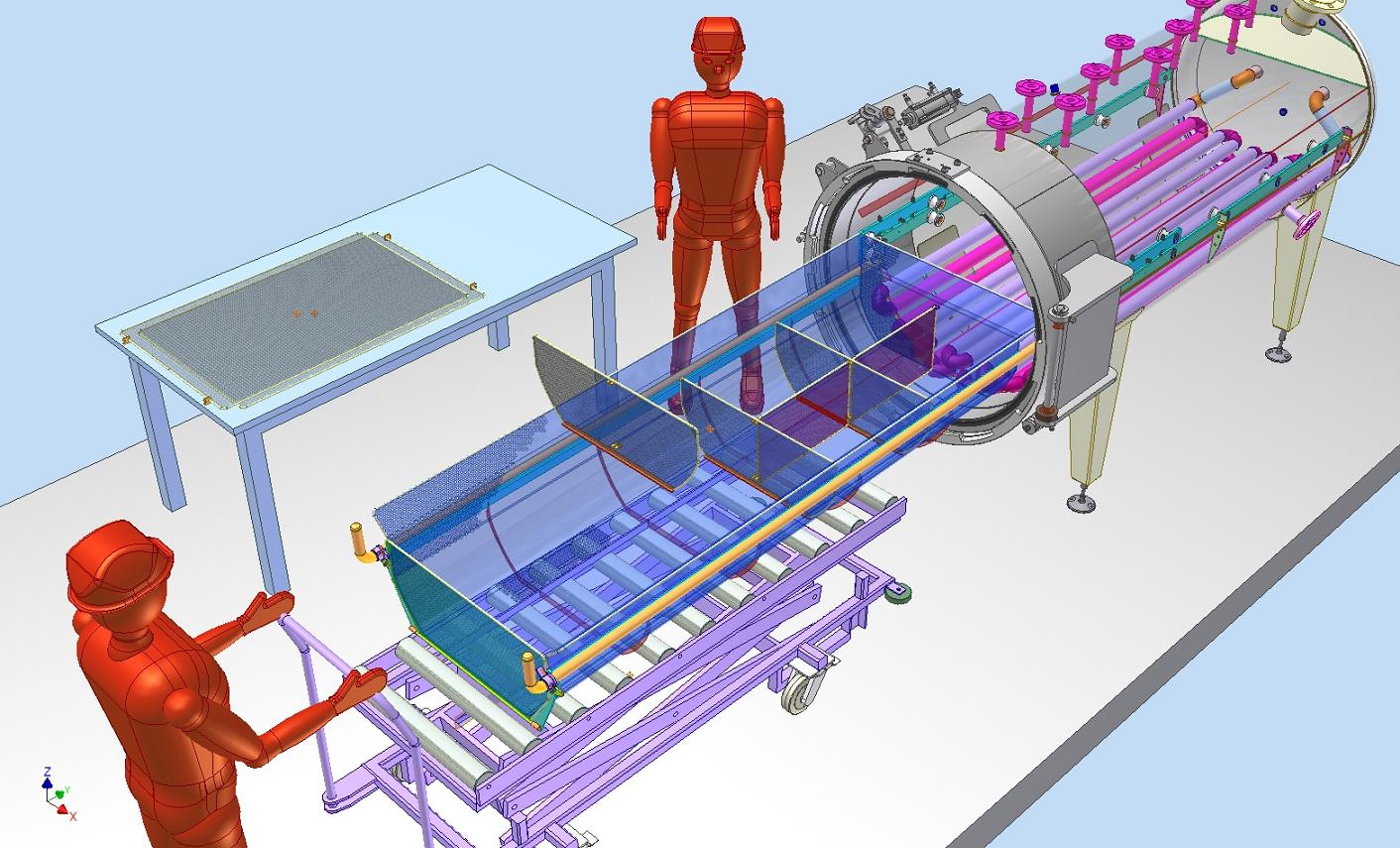

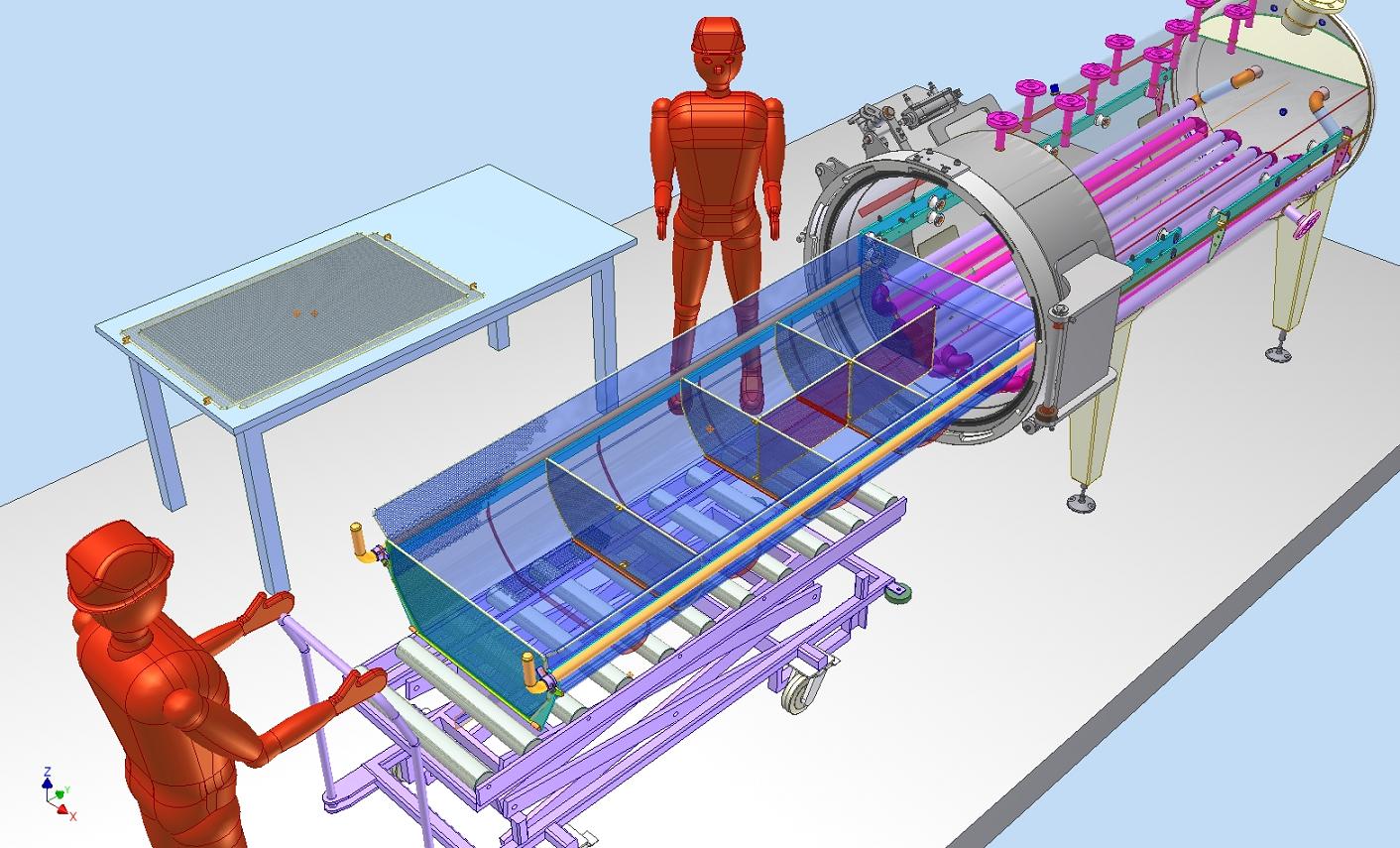

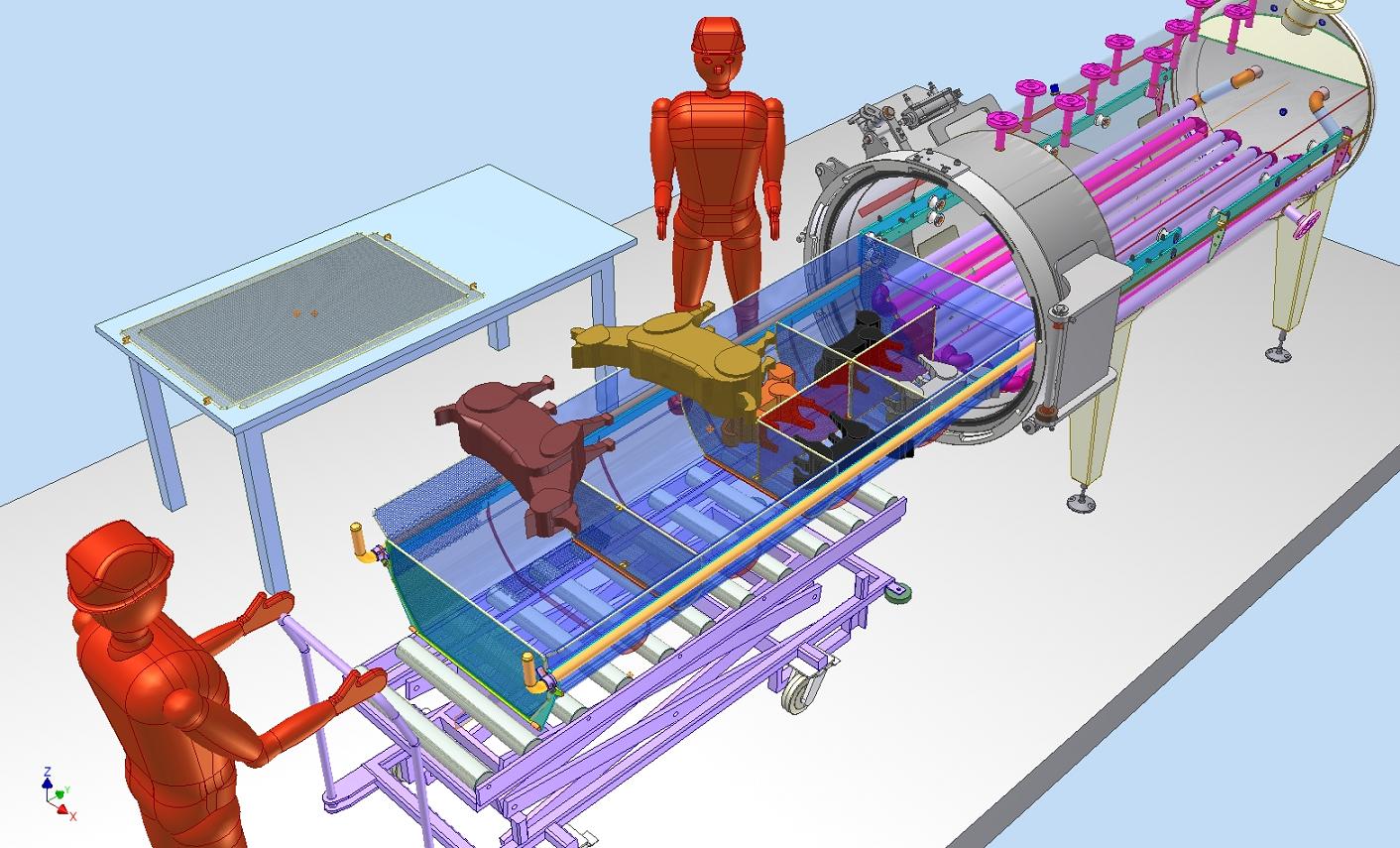

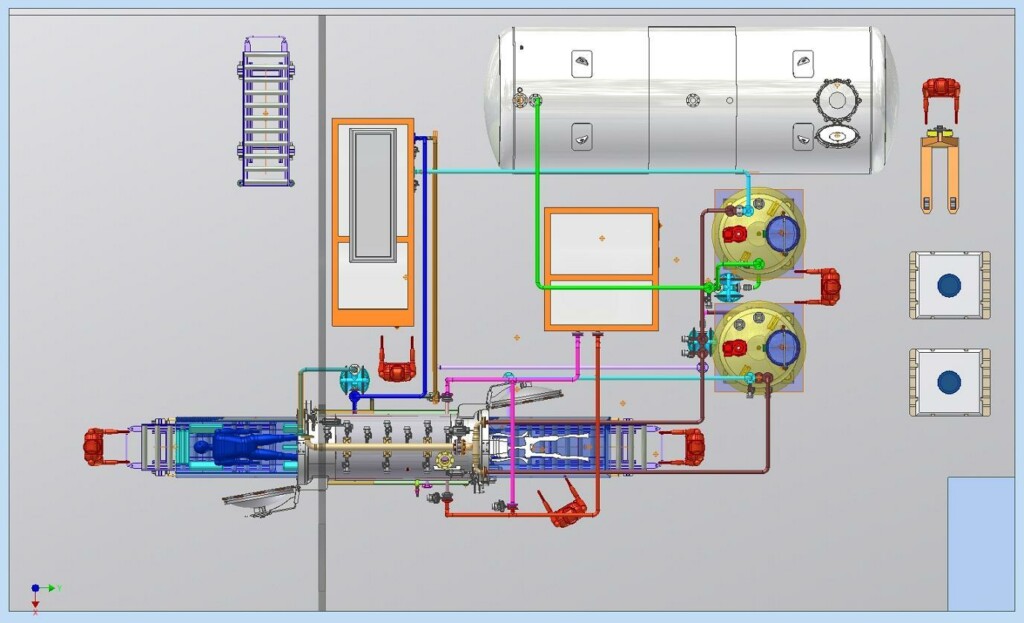

Alka Eco Liquification (Alkaline hydrolysis)

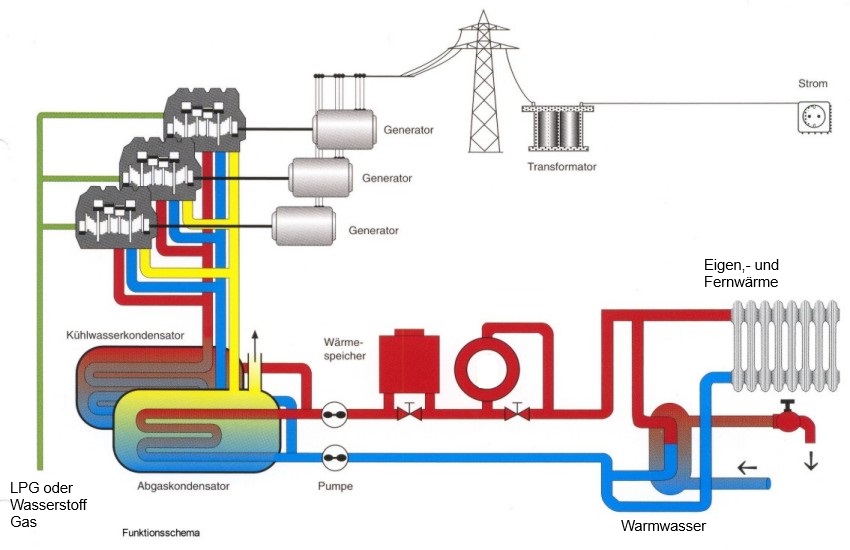

In our December 2024 generation, Alka Eco Liquification Systems, we achieved, huge energy savings through the new energy recall system!

You can save a lot on monthly energy costs. The listed KW are BEFORE THE ENERGY RECALL SYSTEM and estimated.

In start mode, the total power consumption is theoretical 185KW, but that is gross usage.

Since our energy recall system is generating savings of 50-80%, the gross usage of KW is not fully applicable, because each new cycle, with re usage of the hot Effluent, your total cost is already much lower.

To reuse the hot effluent, you will save a lot on the cost of KOH, energy to cool down the Effluent, and to heat it up for the next cycle. This cost a lot of extra energy. This extra energy is now saved, when the hot Effluent is reused.

In general:

You will also save monthly a lot on water, chemicals cost, energy usage. The total energy savings depend on the configuration you choose.